Fuel Cell Reactor

A thesis presenting a novel Swiss roll combuster design enabling use of dual-chamber solid oxide fuel cells

Duration

1 year

Materials

Dupont VESPEL plastic, solid oxide fuel cells, heating wire, flow controllers

This project was completed as part of an honors thesis I undertook for my BS in mechanical engineering. In it, I designed a special heat exchanger reactor for small solid oxide fuel cells (SOFCs), which I will describe briefly here. I designed and drove the entire project independently with only minor oversight and guidance from my professors and research collaborator.

When I first heard about SOFCs, they caught my interest because they weren't limited to hydrogen fuel and could directly utilize hydrocarbons. Liquid hydrocarbons are substantially more energy-dense than current battery technology (by about 50x), which means SOFCs could bypass battery limitations. A more energy-dense electrical power source would make revolutionary new kinds of technology such as untethered powered exoskeletons practical, which have to be tethered or offer minimal assistance due to energy constraints.

Because of the specialization of the research, there were no professors at my school who were familiar with the topic. I read independently on SOFC research for my junior year and became knowledgable on the state of the art and limitations of the technology. I also cultivated relationships with researchers at other schools to build support for my research ideas and met a professor from another state at an ASME fuel cell conference who agreed to collaborate. He partially oversaw the research, and I met with him periodically at his lab.

Technical background

SOFCs operate at high temperatures and can utilize hydrocarbon fuels ranging from natural gas to biodiesel. Portable electronics are an exciting potential application (because of hydrocarbon energy density), although heat loss poses a serious efficiency problem for smaller fuel cell systems.

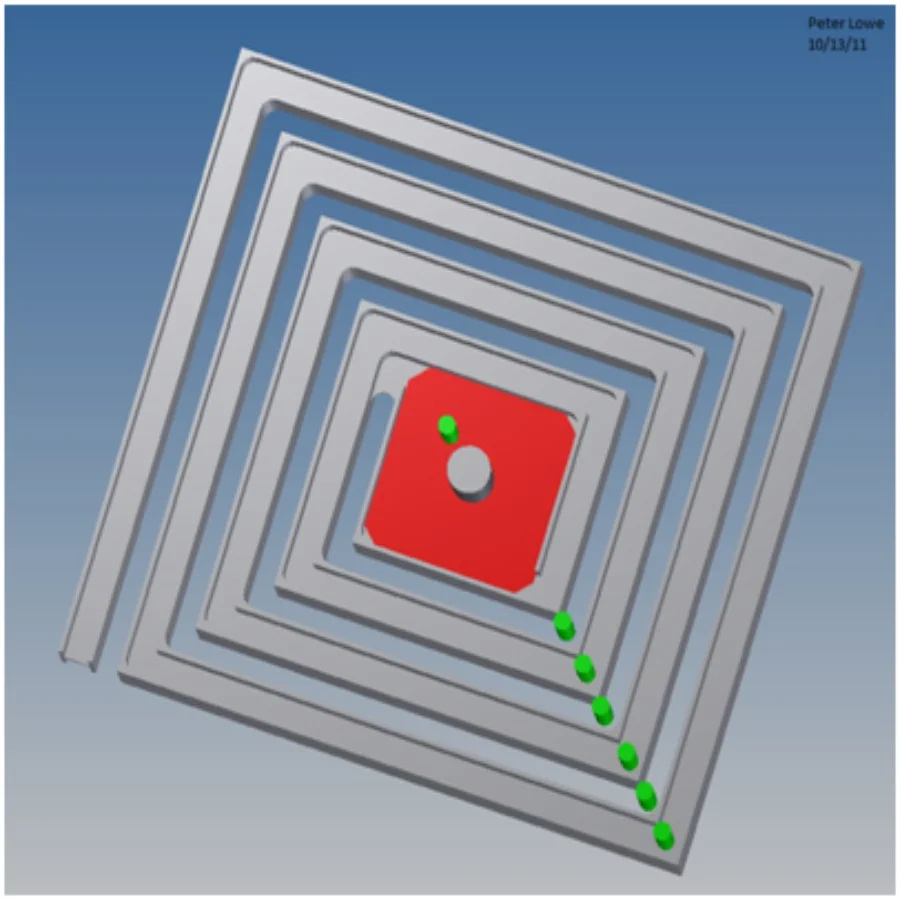

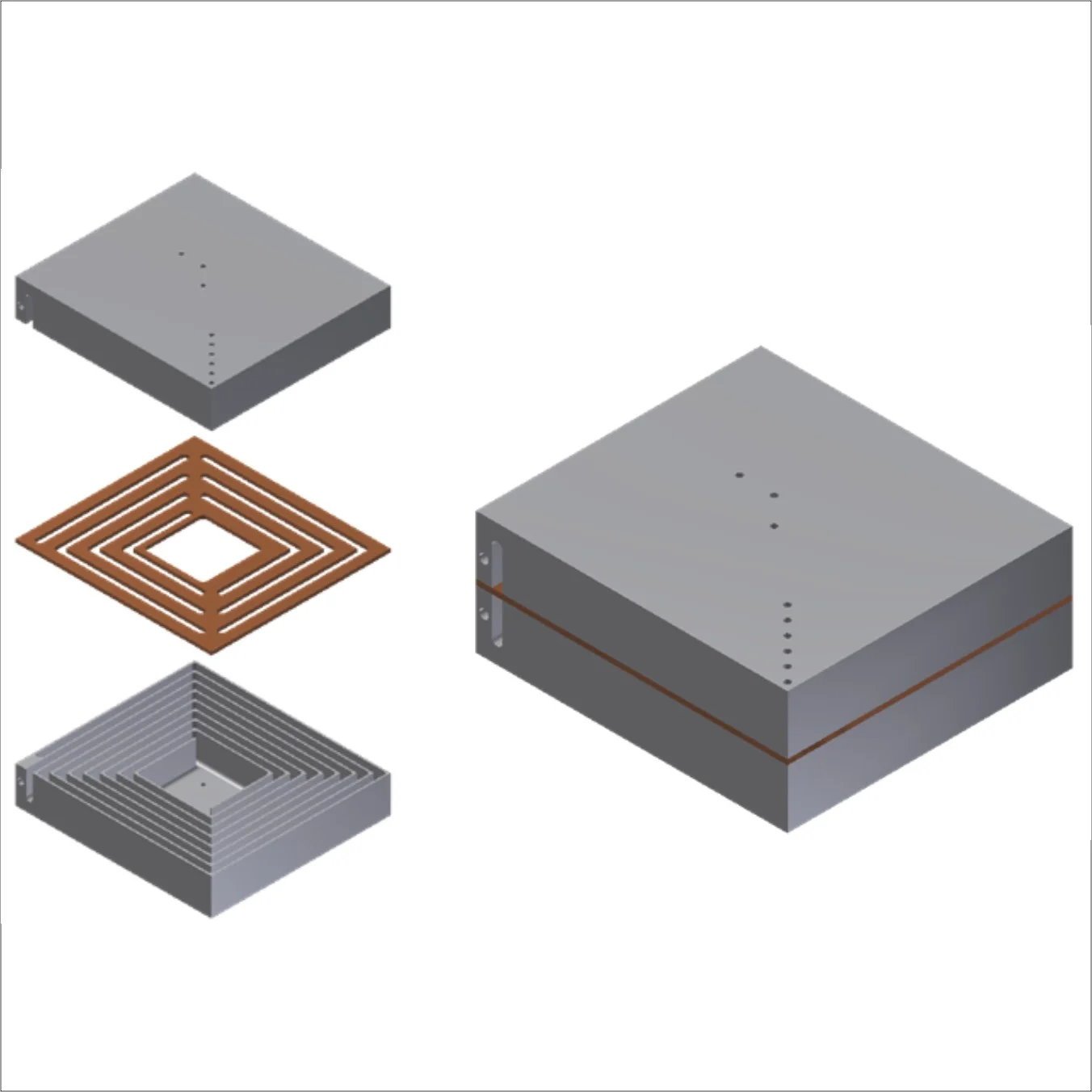

Swiss roll reactors, which behave as a counter-current heat exchanger wrapped around itself with a reaction zone in the center, are a proposed solution to mitigate heat loss. Previous research had used a single channel reactor with mixed reactants and a special single-chamber fuel cell with selective catalysts to utilize the proper reactant on each electrode. However, dual-chamber SOFCs (with fuel and oxidizer exposed to anode and cathode separately) have much greater efficiency, and the thesis idea I developed was to design a Swiss roll reactor which would allow reactants to flow separately through in order to allow use of a dual-chamber fuel cell. My final design utilized a single outlet channel to allow post-combustion of unreacted fuel to provide additional heat for the system.

Thesis Idea

Fabrication

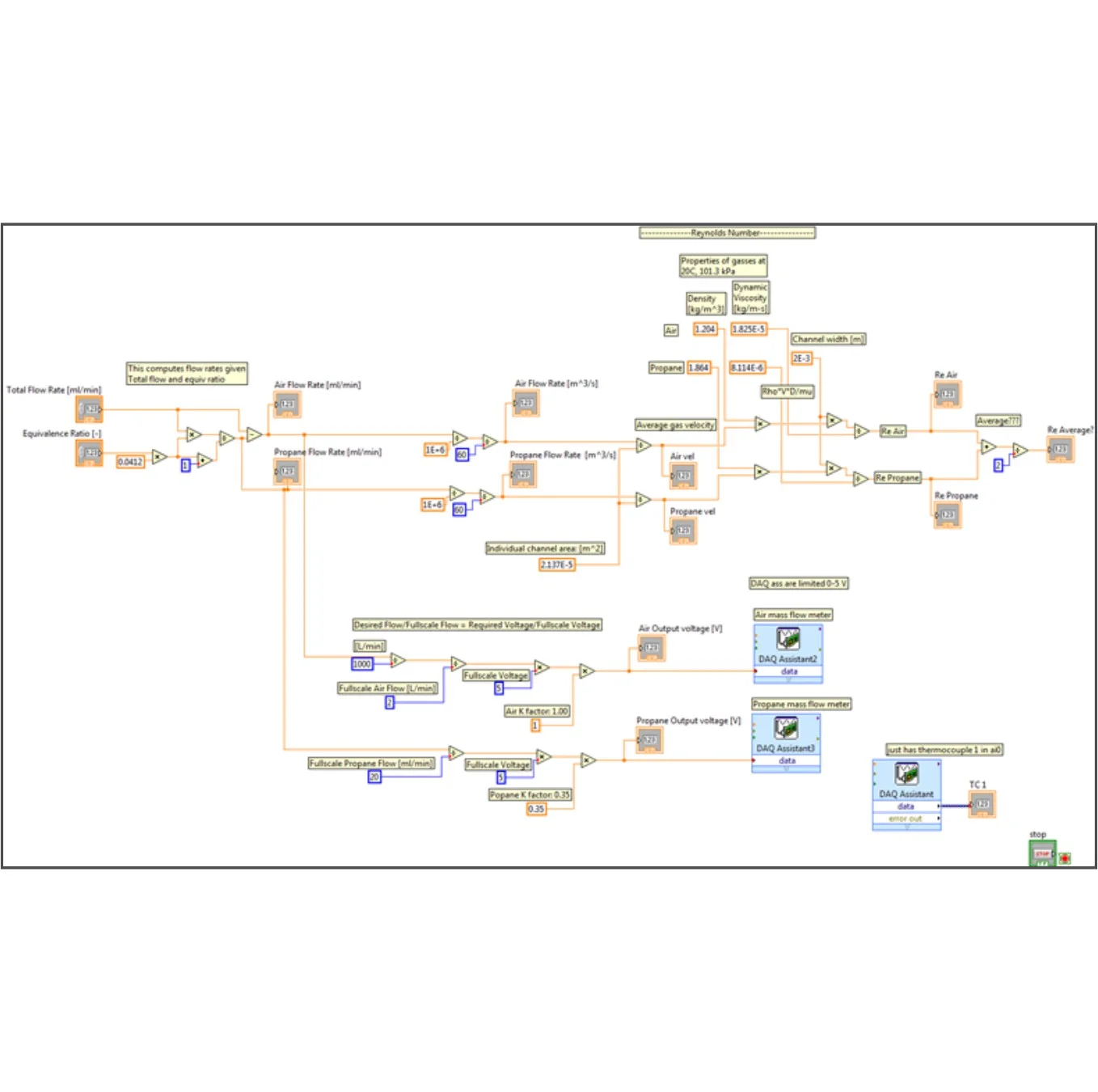

Preparing the experiment

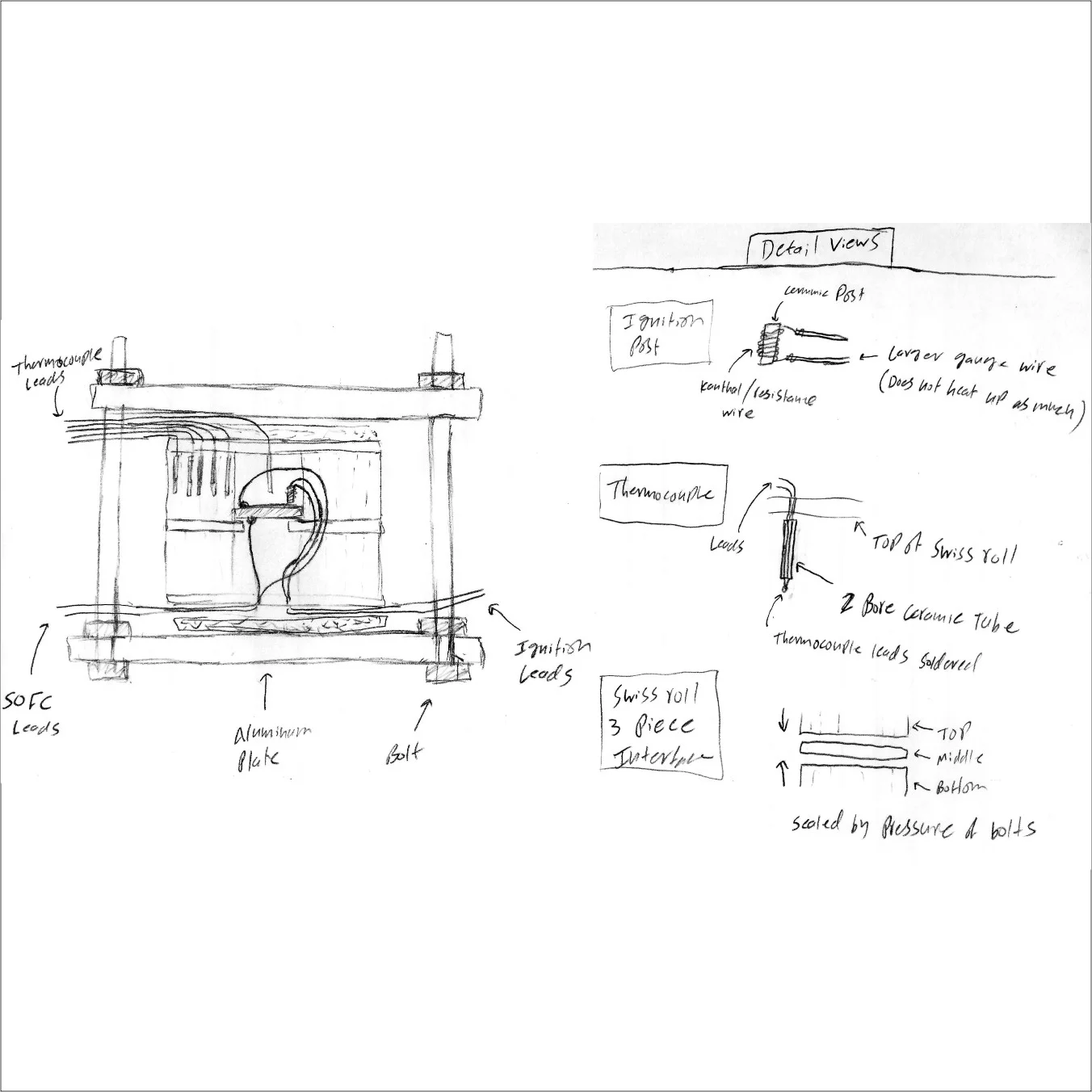

I created my own experimental apparatus at my college to accelerate progress.

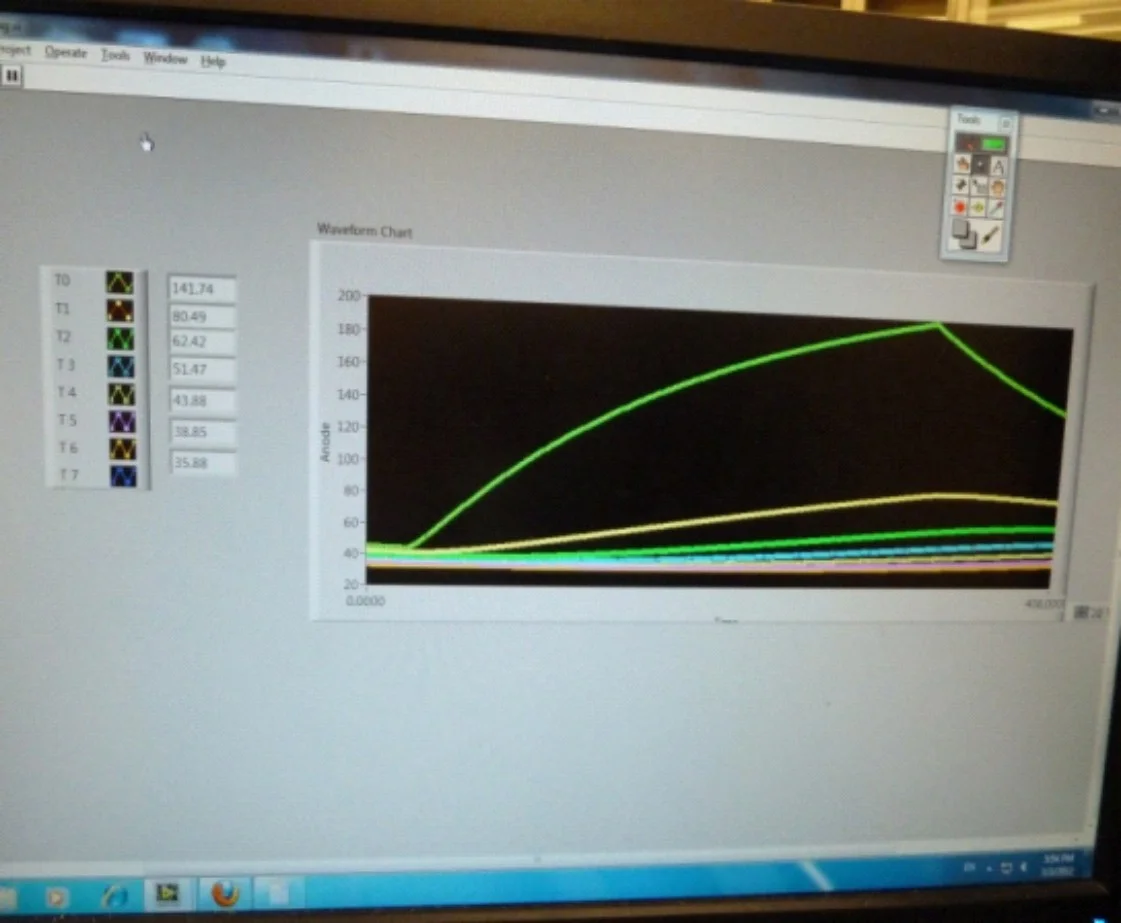

Experimentation

The results from initial tests were promising and indicated the separated reactant design was viable, and the apparatus was handed off to my research collaborator at the completion of the thesis for additional experimentation.